I have long wanted to know about it, and now, finally, I visited the plant in the Voronezh region, which produces Oleina oil. It turns out that he is so famous and huge that for several tens of kilometers citizens go to work. And at its gate we met a whole line of cars - a kilometer long line of trucks that were carrying seeds for processing.

Everything is very strict at the plant - after we were allowed into the territory by special passes, we entered the room where we were told about safety, showed the film. And then dressed so as to protect us, and production. :) Gave helmets, glasses, vests and even boots with socks! And they also asked to remove all the jewelry - such rules at the factory for everyone, without exception, nothing even randomly should fall into the product.

Will you find me? )) I'm sitting next to kak_eto_sdelano and shoots us

muph .

I think in Russia there will not be at least one hostess who would not use sunflower oil. Not surprisingly, our black soil feeds sunflower, which pours its seeds with sun-colored oil.

“Oleina” is manufactured at a modern high-tech factory, where at each stage there is a product - they even use husks, pressing them and selling them abroad for heating, and the cores that remain after oil is extracted from them go to animal feed additives. . The plant, as it turned out, is very powerful - built in 2008 using the latest European technologies, it lets through as many as 540,000 tons of raw materials through it! And at the output it is more than 200 million bottles of sunflower oil a year !! !

Do you know what makes me happy, who visited several Russian factories over the past year? The backwardness and filth, drunk men talking on the mat, and total laxity are gone. Russia has become different - pure form, the best modern design, the latest equipment, iron discipline. Oleina was no exception - it also keeps abreast of science and does not lag behind world quality standards using the latest technologies: when pressing, soft modes of moisture-heat treatment of the core are used, and in the process of physical refining free fatty acids are removed using steam and temperature , which is a more advanced method of purifying vegetable oils than those used before.

These are the biggest cans with vegetable oil that I've ever seen in my life))))):

So, first, the sunflower arrived at the plant goes through the process of separating the husk from the kernels. I was always interested in - how to clean the seeds? it turns out that when they are dried, they become fragile and the machine breaks them, splitting the “packaging” in half. And then the process about which I wrote above is already underway - fats are taken from clean kernels with steam, then the oil is cleaned, refined, deodorized ... Alas, I cannot show the process - we were not allowed into these workshops. Access there is a unit - increased fire risk, people who work there, completely disguised in overalls, which can not cause a random spark from synthetics, and do not use gadgets. The rules are more serious than at the gas station!

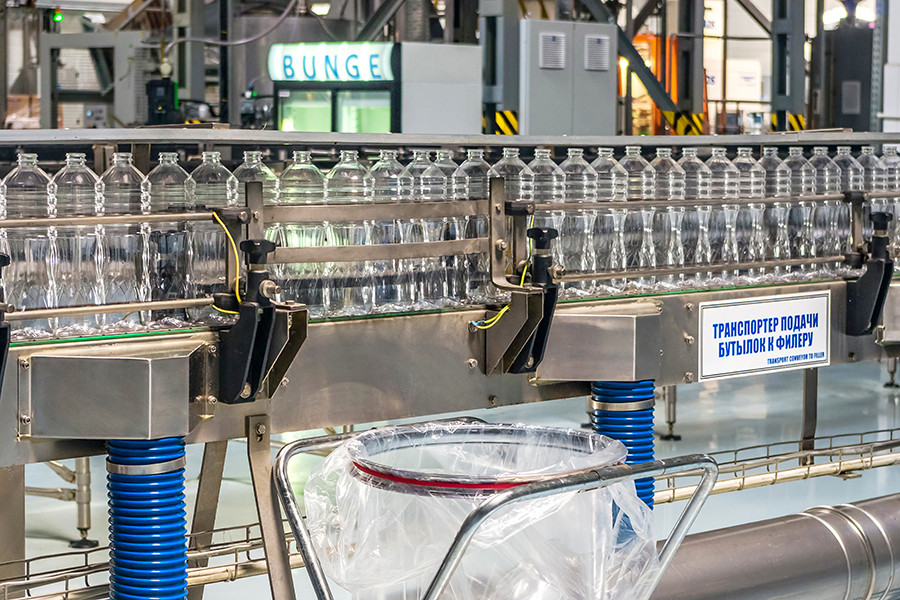

The finished oil enters the bottling shop and now runs along the conveyor. Soon labels will be stuck on it, put in boxes, which will go to warehouses, and from there they will go to the store shelves to get to our kitchens. By the way, the oil of Oleina is made according to this technology, that it is equally well suited for cooking salads and canning, and for frying.

The labeling process is just mesmerizing. =) Would look and look.

Well, this is the final stage - the oil is packed, and the only manual is used here, so to speak, labor - a person uses a lift to transfer it from the tape to the warehouse, and at the factory there is full automation.

Will you find me?

Do you know what makes me happy, who visited several Russian factories over the past year?

I was always interested in - how to clean the seeds?